Do Nascar Engines Have Flat Plane Cranks?

Curious about the inner workings of a flat plane crank and its impact on engine performance?

We explore the advantages and disadvantages of this unique crankshaft design, as well as the types of engines that utilize it.

Dive into the differences between flat plane and cross plane cranks, and discuss whether Nascar engines use flat plane cranks.

Discover the regulations for Nascar engines and how flat plane cranks can benefit their performance.

Learn more about how this crankshaft design affects the sound of a Nascar engine and whether it can be used in street cars.

Key Takeaways:

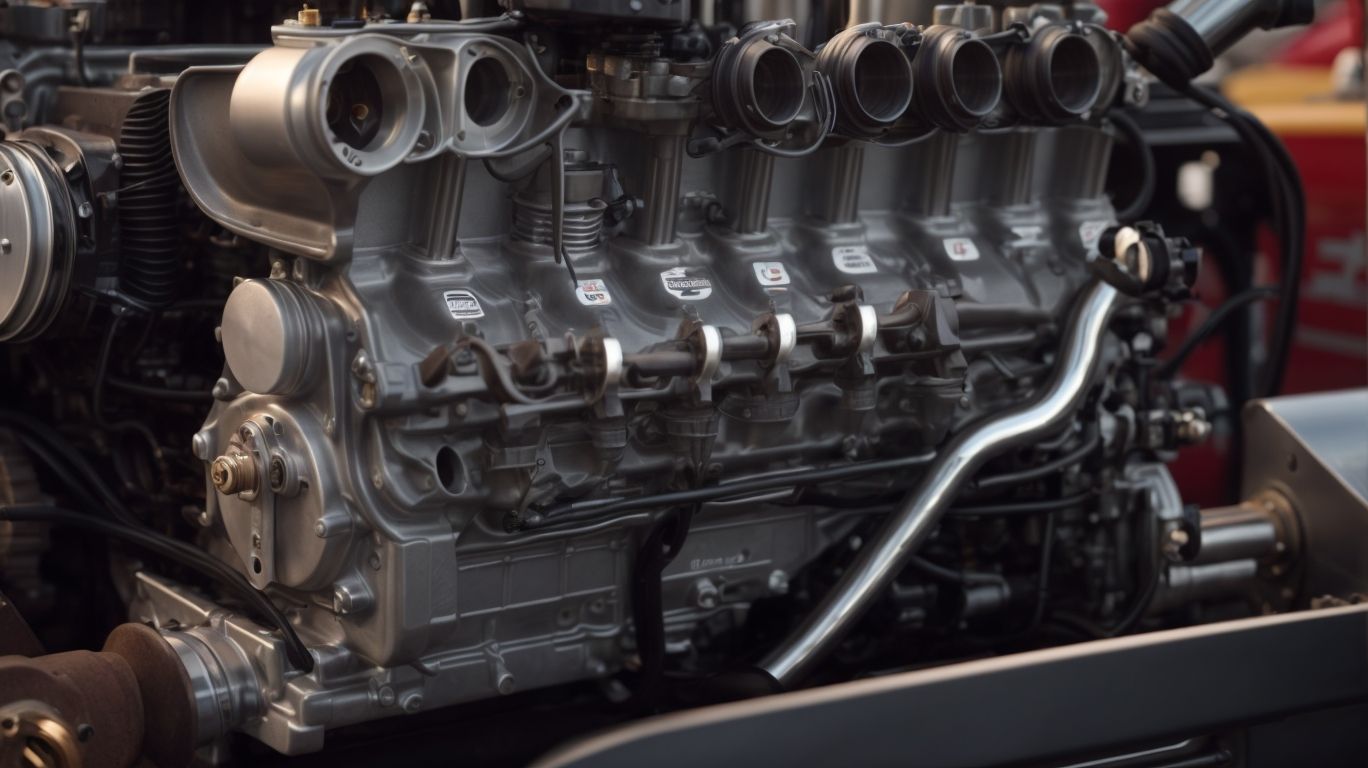

What Is a Flat Plane Crank?

A flat-plane crank is a type of engine configuration in which the crankshaft has its crankpins at 180 degrees. This design creates a firing order that alternates between cylinder banks, leading to a unique engine sound and performance.

Compared to the more common cross-plane crankshaft found in most V8 engines, the flat-plane configuration is well-suited for high-performance applications such as NASCAR race engines. In this setup, the pistons are typically paired with connecting rods of varying lengths to accommodate the 180-degree offset between the crankpins. This arrangement results in a firing order that promotes smoother and more uniform power delivery across the engine’s RPM range.

Engine enthusiasts often appreciate the distinct exhaust note produced by flat-plane crank engines during acceleration.

How Does a Flat Plane Crank Work in an Engine?

A flat-plane crank operates by allowing each pair of pistons to move in unison, enhancing engine balance and performance. In NASCAR engines, this design choice is crucial for achieving high RPMs and horsepower output.

The unique configuration of a flat-plane crank helps to evenly space out the firing order of the cylinders, resulting in a more consistent power delivery throughout the engine revolution. This design is particularly favored in high-revving engines, such as those used in performance cars, because it allows for smoother operation at higher speeds.

What Are the Advantages of a Flat Plane Crank?

The advantages of a flat-plane crank include improved high-RPM performance, enhanced horsepower output, and reduced secondary vibrations compared to cross-plane cranks.

Flat-plane crank designs are particularly popular in the realm of high-performance engines, where precision engineering can make a significant difference in overall output. In the case of NASCAR race engines, which demand exceptional power and reliability, the use of a flat-plane crankshaft can lead to substantial horsepower gains. The design’s inherent balance allows for smoother operation at high speeds, contributing to increased engine longevity and performance consistency. This configuration not only enhances engine efficiency but also offers a distinct sound profile that resonates with motorsport enthusiasts worldwide.

What Are the Disadvantages of a Flat Plane Crank?

Despite its advantages, a flat-plane crank may lead to primary imbalance issues, affecting engine smoothness and requiring additional engineering efforts to address these challenges in NASCAR race engines.

One key drawback of a flat-plane crank configuration is the inherent primary imbalance resulting from the uneven firing order, leading to vibrations and decreased engine smoothness. These vibrations can be more pronounced in high-performance applications like NASCAR, where precision and reliability are crucial.

Engineers face the challenge of mitigating these imbalances through complex counterweight designs, dynamic balancing, and tuning, adding to the overall complexity of the engine system. This requires meticulous attention to detail and testing to ensure optimal performance and durability under the extreme conditions of racing.

What Types of Engines Use Flat Plane Cranks?

Various high-performance engines utilize flat-plane cranks, including V8 engines found in sports cars, as well as Formula One power units known for their high-revving capabilities.

V8 engines in sports cars, like those found in iconic American muscle cars and European performance machines, are renowned for their distinctive exhaust note and sheer power output.

Meanwhile, in the realm of motorsport, Formula One power units stand out for their unparalleled efficiency and incredible rev limits, enabling these high-tech machines to reach mind-blowing speeds on the track.

What Is the Difference Between a Flat Plane Crank and a Cross Plane Crank?

The main distinction between a flat-plane crank and a cross-plane crank lies in the positioning of pistons and rods, affecting primary balance, engine sound, and power delivery.

In a flat-plane crank design, the pistons are arranged 180 degrees apart, providing a firing order that alternates between banks of cylinders, resulting in a more balanced engine rotation. This configuration leads to smoother primary balance but can produce more engine vibrations and a distinct high-pitched exhaust note.

On the other hand, a cross-plane crank features a 90-degree crankpin offset, resulting in an uneven firing order that helps in reducing vibrations and creating a deeper, rumbling exhaust tone. This design improves power transmission to the wheels in certain applications, enhancing traction and stability.

Do NASCAR Engines Use Flat Plane Cranks?

NASCAR engines predominantly utilize flat-plane cranks due to their high-RPM capabilities and power advantages, contributing to the performance seen in NASCAR racing competitions.

This specific crankshaft design allows the engine to revolve faster and more smoothly, essential for achieving the potent power outputs required on the oval tracks of NASCAR races. The flat-plane crankshaft’s unique configuration enhances engine efficiency by reducing internal inertia and promoting better exhaust scavenging, vital for maximizing horsepower and torque in high-performance racing scenarios. By enabling quicker acceleration and improved throttle response, flat-plane cranks give NASCAR drivers the competitive edge needed to outperform opponents in the intense, high-speed environment of professional racing circuits.

What Are the Engine Regulations for NASCAR?

NASCAR has stringent regulations governing engine specifications, with manufacturers like Ford, Chevrolet, and Toyota competing under specific guidelines to ensure a level playing field.

These regulations cover a wide range of aspects such as engine displacement, fuel injection systems, cylinder heads, and exhaust systems. Each manufacturer must adhere to these rules to maintain parity among the competing brands.

Ford, Chevrolet, and Toyota invest heavily in research and development to optimize their engines within these constraints, aiming to gain a competitive edge while staying within the established parameters. This dynamic ensures that the competition remains fierce on the racetrack, with each brand striving to push the boundaries of performance while staying compliant with NASCAR’s strict regulations.

How Do Flat Plane Cranks Benefit NASCAR Engines?

Flat-plane cranks offer NASCAR engines advantages such as optimized power strokes, improved airflow, and enhanced valvetrain stability, contributing to the performance of NASCAR cars.

One of the key benefits of flat-plane cranks in NASCAR engines is the optimized power stroke. Due to the unique crankshaft design, each cylinder experiences more evenly spaced and balanced power strokes, leading to enhanced torque output and overall engine efficiency.

The improved airflow achieved with flat-plane cranks allows for better intake and exhaust gas flow, resulting in increased horsepower and improved engine response at higher RPMs. This enhanced airflow optimization is crucial for NASCAR engines, where every bit of performance gain matters on the racetrack.

The design of flat-plane cranks contributes to valvetrain stability, reducing vibrations and stress on the engine components. This stability not only enhances engine durability but also promotes smoother operation, crucial for long races where reliability is paramount.

Are There Any NASCAR Engines That Don’t Use Flat Plane Cranks?

While flat-plane cranks are common in NASCAR, some manufacturers may opt for other configurations based on performance preferences and engine design requirements.

For instance, Chevrolet has been known to utilize a cross-plane crank layout in some of its NASCAR engines. This choice is often rooted in the inherent torque characteristics of the cross-plane design, providing a balance between power delivery and engine smoothness.

On the other hand, Ford has often stuck with flat-plane cranks, leveraging their ability to enhance high-end power and engine response. The flat-plane design allows for improved exhaust scavenging, promoting better performance at higher RPM ranges.

How Does a Flat Plane Crank Affect the Sound of a NASCAR Engine?

The flat-plane crank design influences the unique exhaust note of a NASCAR engine, creating a distinctive high-pitched sound associated with high-revving performance machines.

This crankshaft type is known for its 180-degree crankpin design, contributing to a firing order that alternates between cylinder banks, resulting in a more balanced engine operation.

The firing sequence of a flat-plane crank engine leads to quicker acceleration and higher engine speeds, which in turn, enhance the overall performance of the vehicle.

Can Flat Plane Cranks Be Used in Street Cars?

Flat-plane cranks can be integrated into street cars like the GT350, providing benefits such as increased specific output and a unique engine sound profile reminiscent of racing vehicles.

One of the key advantages of using a flat-plane crank in a street car like the GT350 is the improved overall performance it offers. The design of the flat-plane crankshaft allows for more optimal firing order, resulting in smoother power delivery and better throttle response.

This enhanced specific output not only boosts horsepower and torque figures but also makes the engine feel more responsive and eager to rev, characteristics highly sought after by performance enthusiasts.

What Are the Benefits of Using a Flat Plane Crank in a Street Car?

Integrating a flat-plane crank in a street car can improve specific output, enhance engine responsiveness, and provide a unique driving experience reminiscent of high-performance vehicles.

One of the key advantages of opting for a flat-plane crankshaft design in a street car is the significant boost in specific output it can deliver. By allowing for more efficient exhaust scavenging and reduced internal inertia, this configuration enables the engine to produce more power per liter compared to traditional designs.

The use of a flat-plane crank can greatly enhance engine responsiveness, translating to a more immediate throttle response and smoother acceleration. This enhanced agility and rev-happy nature make the driving experience truly exhilarating, especially for enthusiasts seeking a spirited performance on the streets.

Are There Any Drawbacks to Using a Flat Plane Crank in a Street Car?

Despite its benefits, incorporating a flat-plane crank in a street car like the GT350 may lead to increased engine vibrations and potential drivability challenges that need to be addressed for optimal performance.

In high-performance vehicles such as the GT350, where precision and performance are paramount, engine vibrations caused by a flat-plane crank can significantly impact the driving experience. These vibrations can lead to discomfort for passengers, affecting the overall comfort level in daily use. The drivability challenges associated with this design can pose difficulties in low-speed maneuvering and city driving, where smooth power delivery and responsiveness are crucial.

Frequently Asked Questions

Do Nascar Engines Have Flat Plane Cranks?

No, Nascar engines do not have flat plane cranks.

What type of crankshaft do Nascar engines use?

Nascar engines use a cross-plane crankshaft, which is different from a flat plane crankshaft.

Why don’t Nascar engines use flat plane cranks?

Flat plane cranks are typically found in high-performance, exotic cars and are not suitable for the demands of Nascar racing.

What are the benefits of using a cross-plane crankshaft?

A cross-plane crankshaft allows for better torque and power delivery, which is important for the high speeds and intense racing in Nascar.

Are there any other differences between flat plane and cross-plane crankshafts?

Yes, flat plane cranks have a 180-degree firing order, while cross-plane cranks have a 90-degree firing order. This affects the engine’s sound and performance.

Do all Nascar engines use the same type of cross-plane crankshaft?

No, Nascar teams may use different variations of cross-plane crankshafts, such as a D-shaped crank or a split-pin crank, to optimize their engine’s performance.